Introduction

Since its introduction in the 1980s, leading industry authorities have been aware of the revolutionary advantages of additive manufacturing. Unlike subtractive manufacturing where the process begins with a solid block of material that is cut away until the finished product is created, additive manufacturing builds a product or part layer by layer based on the 3D design, usually created on Computer Aided Design (CAD) systems or from a 3D scan of an existing part.

This building-up method offers several advantages including:

- Design freedom and flexibility – various design iterations can be tested rigorously

- Reduced time to market – parts can be produced more quickly to meet market demands

- Lowered manufacturing costs and material waste – only the material required for the design is used

- Improved product quality and performance – this technology enables the creation of better products with complex designs

Table of Contents

Conformal Cooling vs. Straight-line Cooling

As additive manufacturing technology became even more sophisticated, additional benefits became more apparent. Conformal cooling, being an industry game-changer, has been the talk of the town among plastic mold manufacturers.

In conventional injection molding processes, molds have straight-line cooling channels created by drilling straight-line holes into the mold. Cold water runs through these channels to cool down the core, pulling heat away from the plastic part. This works well with a majority of simple-shaped plastic parts; but for more complex shapes, these straight-line channels are not as efficient in drawing heat away and may result in end part warpage and longer cycle time, which ultimately affects product quality and company profits.

The solution: conformal cooling channels. This cooling technique makes use of cooling channels that are not straight; the channels “conform” or adapt to the contours of the part being molded. These free-form channels draw heat away from the irregularly-shaped molded part much more effectively than straight-line channels, and are made possible by additive manufacturing technology.

Benefits of Conformal Cooling

Fewer Rejects, Reduced Recall

Conformal channels make uniform cooling possible for complex molds. This helps reduce the likelihood of rejecting final parts due to warping and costly recall of products. The reduction in reject costs and risks of recall are inherently beneficial to a company’s profits.

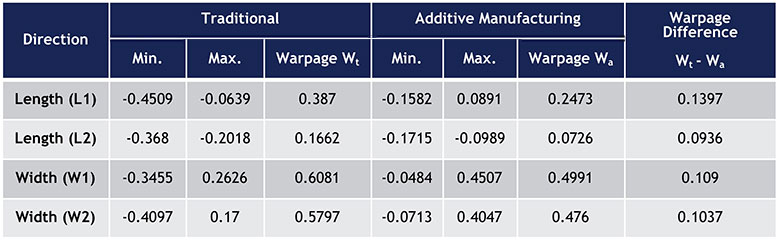

In an experiment using two different cooling fluids, the experiment data shows that additive manufacturing molds with conformal cooling channels consistently produce final parts with less warpage in all directions, regardless of the cooling fluid used.

Higher Production Rate

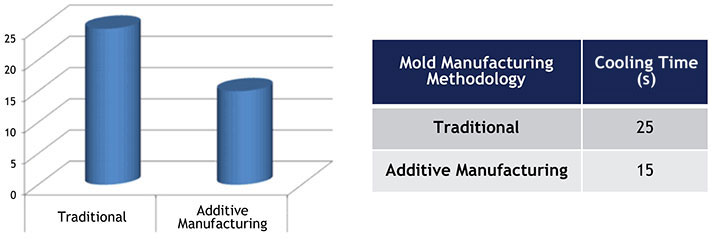

With a shorter and more consistent cooling time, cycle time is also reduced, which results in higher production rates. In a study comparing cooling time between traditionally manufactured molds and additive manufacturing molds, with all other parameters (e.g. dry preparation, melt temperature, mold temperature, molding speed, etc) being the same, the latter showed a reduced cooling time of 10 seconds.

Improved Product Quality

Since conformal cooling enables a consistent cooling rate over the plastic surface, molded-in stress can be reduced. This yields a stronger part, which ultimately increases part safety and quality.

With these proven benefits, conformal cooling by additive manufacturing can be highly recommended to companies operating in industries with a high risk of product liability— for example, automotive, medical & life sciences, and food & hygiene end applications.