Introduction

Busbar connectors are important components in power generation modules. Over the years, they have undergone multiple iterations, evolving in tandem with the trend of power applications and systems becoming smaller, faster and more complex.

In this article, we look at what busbar connectors are and their evolution through the years.

What Are Busbar Connectors

In power-intensive applications, busbars (often also spelled bus bars or bussbars) are critical interfaces for conducting significant current levels between functions within an assembly. They are typically a strip, a bar or sometimes a tube made of copper, brass or aluminum optimized for current requirements and performance specifications.

Busbar connectors are parts used to connect busbar systems to the power module or other parts of the assembly.

Applications of Busbar Connectors

With the new generation of power applications getting smaller and more complex, it becomes less feasible to connect busbar systems using conventional methods such as bolting, welding, or clamping connections.

Soldering is problematic too, with a busbar’s heat dissipation qualities making soldering impractical as part of mainstream automated assembly processes. This often requires specialized secondary manual soldering steps, making it time consuming and costly.

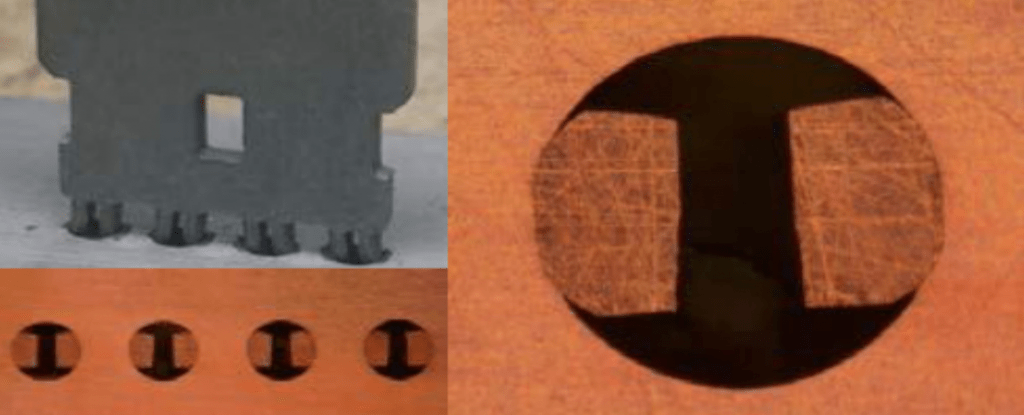

Solderless interconnects, such as Press-Fit technology, provide a great solution to these issues. Not only do they provide excellent conductivity, they also eliminate the need for soldering.

While some designers have been hesitant to adopt Press-Fit to connect directly with copper busbars— due to a misconception that at high temperatures, the copper creep may weaken the interconnects over time and degrade overall performance— tests conducted have shown that the functionality of high force Press-Fit connections are well-maintained through the creep of the copper busbar.

Busbar Connectors and Industries We Serve

Interplex has over 30 years of industry-leading experience in designing, manufacturing and customizing advanced interconnects for a wide range of industries and specialized applications.

With our expansive global manufacturing footprint and localized production facilities, we enable customers to incorporate advanced interconnect technologies into products built anywhere in the world, while maintaining the highest quality and keeping both logistics and product costs competitive.