Overview

Hydrogen fuel cells represent an important enabling technology in the shift from fossil fuel engines to electric vehicles. Starting from when The First Hydrogen Fuel Cell Vehicle was Created in 1966, many advances in fuel cells technology over ensuing decades have now set the stage for broadening adoption of this cleaner and more sustainable power alternative across a wide range of applications in a multitude of industries.

As discussed in this Tech Bulletin, a critical factor in today’s advanced fuel cells is high-volume, high-quality production of the multiple bipolar plates (BPPs) at the heart of the energy generation process within Proton Exchange Membrane Fuel Cells (PEMFCs).

The Vital Role of Fuel Cell Bipolar Plates

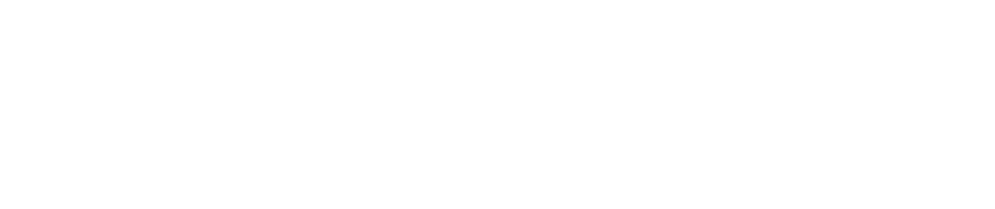

As shown below, multiple BPPs, with a Membrane Electrolyte Assembly (MEA) between each BPP, are combined within the PEMFC to provide the required level of electrical energy production, in much the same way that cells in a battery collectively combine to deliver specified output levels.

Fig 1. Bipolar Plate Assemblies in PEMFC

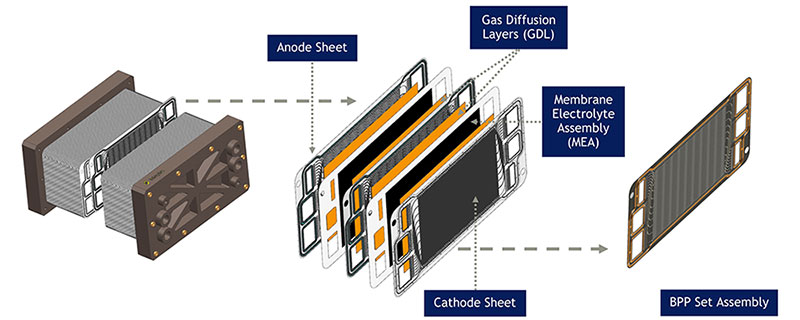

Each BPP consists of multiple components, as shown below, which must be assembled in a very consistent and precise manner.

Fig 2. Bipolar Plate Components

Key Steps for Successful Production and Assembly of Bipolar Plates

To function properly, BPPs need to conduct electricity from one cell to the next. The accuracy of geometry and shape is very important; a precisely-shaped geometry assures an even contact resistance and uniform distribution of current and heat over the whole BPP. This gives rise to a more reliable and energy-efficient PEMFC. In addition, the BPP gasket must also prevent gases from passing across to the other side of the cell, a condition known as “gas crossover”.

Backed by many years of experience in producing high-precision metallic parts combined with integrated rubber in high-volume production, ENNOVI is trusted by top-tier customers to provide customized solutions tailor-made for automotive, transportation and industrial end applications.

By leveraging this deep experience, ENNOVI is well-equipped with capabilities and the expertise required to produce components such as BPPs in high volumes with precise control of the following key production steps:

- High-precision stamping

- Laser welding

- Physical Vapor Deposition (PVD) coating

- Gasket overmolding

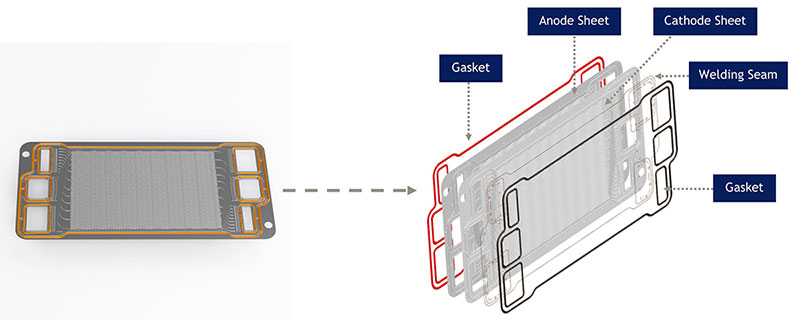

Stamping

Hydrogen and Oxygen react on the MEA in between each BPP to generate electricity and pure water as waste. The MEA can be seen as the heart of the fuel cell, with the BPPs being the veins that distribute gases (Hydrogen and Air) and effectively transport electricity.

Undoubtedly, precision is of utmost importance for such a critical component in fuel cells. Successfully achieving high production volumes requires tight control over progressive stamping processes, along with high-precision CNC technology and rigid presses, and fast automated feeding systems.

Fig 3. Anode Sample

Fig 4. Stamping Equipment

Laser Welding

Laser welding is an effective bonding method for joining thin metallic BPPs to achieve a reliable seal, resulting in a seam of high mechanical strength. Success in the laser welding step is best achieved with a unified single-jig approach for the entire welding process.

Sustained high-volume throughput requires automated loading, clamping and unloading of the parts. Achievement of quality requirements depends on 100% welding quality leakage testing.

Fig 5. Welding Line Details

Fig 6. Laser Welding Equipment

Physical Vapor Deposition (PVD) Coating

PVD coating is used on the BPPs to provide corrosion resistance and maintain low electrical contact resistance. For best PVD coating performance and to achieve high throughput, high-precision production steps as well as good quality control is imperative.

Fig 7. PVD Coating Equipment

Fig 8. PVD Coating on Both Sides

Gasket Overmolding

Gasket overmolding with silicon or EPDM rubber material requires high-precision processes capable of one-time molding of both anode and cathode sides, while avoiding any deformation on the BPP flow channels.

Fig 9. Gasket Overmolding Equipment

Fig 10. Double-sided Gasket Assembly

Finite Element Analysis and Testing

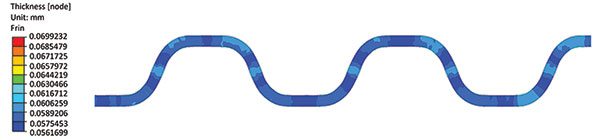

As achieving a precise and consistent form factor is critical to the successful operation of the BPPs, extensive analysis of the design using Finite Element Analysis (FEA) is imperative and used at ENNOVI. FEA enables designers to measure and confirm the following crucial parameters in order to ensure they function as desired:

- Forming parameters

- Material thinning ratio

- Overall flatness

- Channel height

- Channel flat area

Fig 11. Finite Element Analysis of Flow Channels

Key parameters need to be maintained within very tight tolerances, for example:

- Channel height: ±0.015mm

- Thickness evenness: 8% (active area)

- Thickness thinned ratio: 25% (existing sample)

- Channel flat width: ±0.03mm

- Channel pitch down to: 1.0 mm (for BPP raw material thickness of 0.075 – 0.1mm)

In addition to upfront design verification with FEA and production sampling to assure these critical parameters are within their acceptable ranges, it is also a good practice to perform 100% leak testing in production.

Summary

PEMFCs are projected to be of significant influence in the predicted shift away from fossil fuel energy sources to greener and more sustainable ones. For this to effectively materialize, it requires the development of manufacturing methods that can cost-effectively produce the BPPs that are critical to the PEMFC system.

To successfully achieve the required volume production levels, fuel cell makers will need to establish close design and manufacturing relationships with reliable partners capable of supporting the entire process; including initial design, FEA analysis, prototyping and ramp-up to high-volume commercial production, while maintaining the tight quality parameters required for success.

For More Information

For more information, email us at communications@ennovi.com.