Overview

The global market for electric vehicles (EVs) continues to accelerate rapidly as multiple waves of technology innovation address and resolve many of the key challenges that previously hampered widespread adoption. One of the most important areas of progress is in battery technology, with goals of lowering battery cost, improving performance and extending battery life.

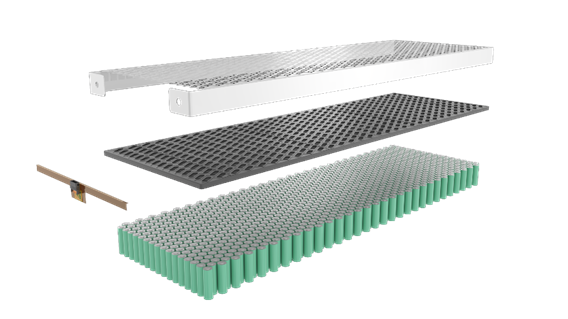

Interconnect Solution for Tight Spaces and Weight Constraints

ENNOVI has long been a recognized leading innovator in the EV sector and has already transformed the options available to battery designers with the Cell-PLX™ battery interconnect system that provides a single robust, customizable, cost-effective solution to address the full range of requirements across the entire spectrum of EV applications.

Cell-PLX™ provides options for high speed, robust laser weld attachment from collector plates to the cells, thereby enabling efficient production processes, lower manufacturing costs, and high-volume operations. This gives battery designers an interconnect solution that is very thin and light to fit into tight spaces and weight constraints, while also being extremely robust.

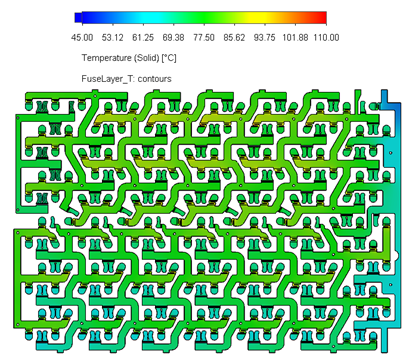

Cell-PLX™ Patent-pending U-Turn Technology

With the introduction of new patent-pending “U-Turn” design options, ENNOVI has now further expanded the Cell-PLX™ technology to address another key issue, which is the tendency for EV batteries to develop hot-spots within the current flows across collector plates.

U-Turn technology addresses this issue and mitigates internal hot-spots by providing excellent current density spread and uniform distribution of current density throughout the entire battery module. By reducing stress on the individual battery cells, U-Turn enables optimal battery performance and increases EV range, while also improving battery lifespan.

ENNOVI is able to achieve this evenly distributed power spread by leveraging our proven, precision, high-volume manufacturing methods that ensure each Cell-PLX™ metal plate has a consistent thickness, even for very large battery interconnects.

Key benefits of U-Turn design:

- Provides even spread of current throughout the battery

- Eliminates current bottlenecks that cause temperature spikes

- Distributes uniform current density across the battery

- Eliminates hot spots which prevents degradation of battery life

These improvements further enable battery manufacturers to improve battery management and charging systems to optimize both charging efficiency, range per charge, and extended battery life.

From an overall EV market perspective, these innovations help to mitigate three of the key concerns that have impacted adoption to date, thereby improving both market acceptance of EVs and enhancing achievement of automakers’ business goals.