Overview

This Did You Know is part of a series that explores the Five Key Challenges to Widespread Adoption of Electric Vehicles (EVs). In this article, we drilldown to take a closer look at the issue of “EV Range Anxiety”.

EV Price vs Range Trends

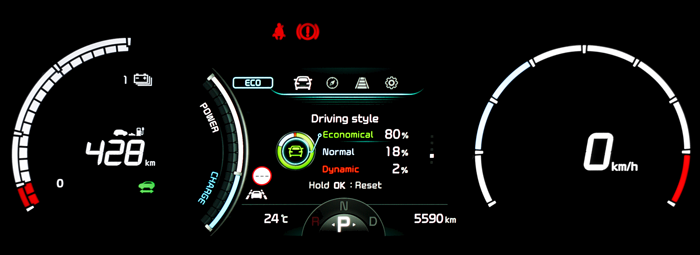

Battery capacity is the most important factor for range. Most EVs only need about 20-30 kilowatts to move at a steady speed so, depending on the situation, a 60-kWh battery could enable about three hours of driving. Of course, factors such as speed, temperature and other driving conditions can impact the rate of battery usage. Other factors that can impact an EV’s battery life are weather, battery age and charge capacity.

Currently, in the EV market there is a clear direct correlation between longer range and a higher price for new EVs. According to Kelly Blue Book the top 10 longest-range electric cars in 2022 are led by the Lucid Air Dream Edition with a stated range of 520 miles per charge on a 118-kWh battery, followed by the Tesla Model S at 405 miles per charge on a 100-kWh battery. These and other EVs in the on the top 10 list tend to be among the highest priced EV offerings

On the lower cost end of the spectrum are EVs such as the Mini Cooper SE with a range of 110 miles per charge on a 28.9-kWh battery. The mid-range sector is becoming more competitive with models such as the Chevrolet Bolt with an EPA-estimated range of 259 miles at a starting price of $37,495, which is equivalent to the Tesla Model 3 with its range of 240 miles.

While range anxiety is a real factor in market perceptions, it is also important to keep in mind the actual driving requirements for most consumers. According to Coltura.org, “Many electric vehicles already have enough range (100 to 200 miles) for the vast majority of people and the vast majority of trips… 68% of commutes in the US are less than 15 miles each way, and 89% are less than 35 miles.”

Other Key Considerations Impacting Range

Other factors that can impact an EV’s battery life are weather, battery age and charge capacity.

From a weather standpoint, very low ambient temperatures can negatively affect a battery’s ability to hold a charge. In addition, hot or cold conditions typically mean more use of cabin climate controls, which draws down battery power to keep passengers comfortable.

As an EV battery ages, it loses some of its maximum charge potential, however, the degradation is slow (about 2.3% per year) and with federally mandated eight-year, 100,000-mile battery warranties, EV batteries can be expected to perform well over time.

Charge capacity is likely the factor that drivers most need to understand because automakers intentionally use complex battery systems that limit maximum charging capacity in order to prolong overall battery life. Typically, rapid charging stations can quickly bring an EV up to 80% charge in as little as 30 minutes, but it is not advised to regularly charge to 100%. From an expected driving range standpoint, drivers need to keep this charging limit in mind to effectively plan their recharging stops.

The best practice for balancing daily driving range and preserving long battery life is to keep the routine charging level above 20 percent and below 80 percent of total capacity. Charging to 100 percent should be reserved for those instances where the extra distance is going to be needed.

Battery Technology Innovations

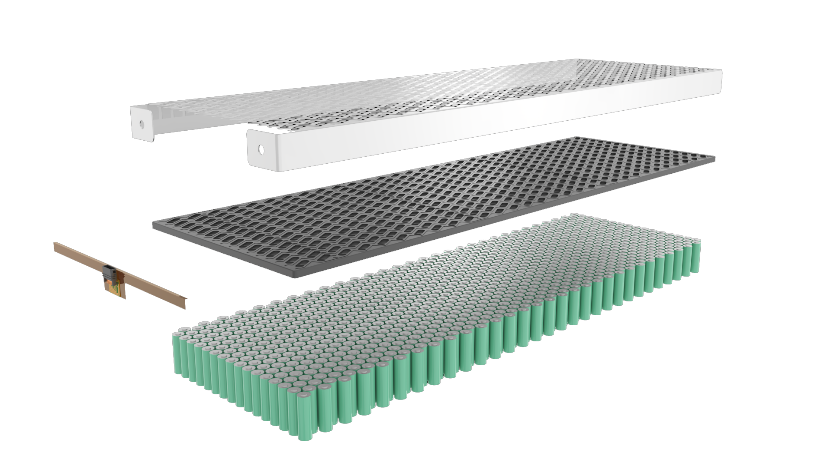

EV batteries generally consist of a design hierarchy including the following key elements:

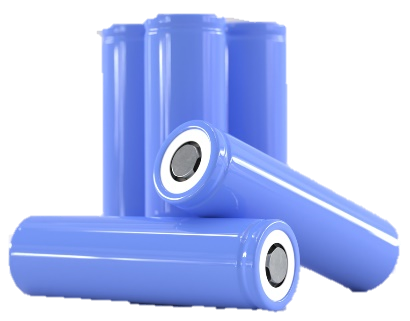

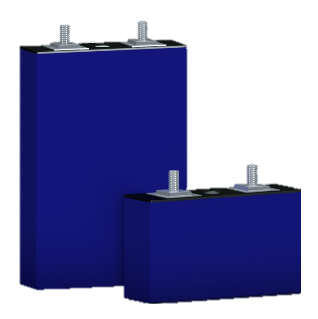

- Individual Cells – the smallest, packaged form of battery, which typically is a Lithium-ion unit delivering one to six volts each.

- Modules – typically consisting of several cells connected together in either series or parallel.

- Battery Packs – final deployable battery systems consisting of multiple modules combined in series or parallel to provide the level of output needed for a specific application.

Individual cells can take a range of different shapes, including cylindrical, pouch or prismatic.

Battery modules consist of a large number of individual cells grouped together and connected to current collector plates for gathering the specified power output levels. The number of cells connected in a specific configuration and power output of each cell are the determining factors for delivering the required output for the battery module.

Keys to efficient price-to-performance for a range of requirements include:

- Flexibility to handle different cell types

- Robust laser weld or wire bond attachment options for connect cells to collector plates

- Customization capabilities to meet any power output and configuration requirements

- Ability to handle design-specific requirements for aluminum, copper, nickel, performance plastics, dielectric layers, etc.

- Optimized packaging to accommodate harsh vibration and environmental specifications

With exponential proliferation of EV and other e-Mobility applications around the world, each battery design has unique requirements. So customized solutions are critical to support a wide range of designs.

The Cell-PLX™ battery interconnect system from ENNOVI is specifically designed to enable battery manufacturers across the entire spectrum of applications to have a single robust, customizable, cost-effective solution that addresses the full range of design requirements.

Cell-PLX™ gives battery designers an interconnect solution that is very thin and light to fit into tight space and weight constraints, while also being extremely robust.

To enhance designs for cylindrical battery cells, Cell-PLX™ uses a patented innovation called U-Turn, which provides excellent current density spread and uniform distribution of current density throughout the entire battery module. By reducing stress on the individual battery cells, U-Turn enables optimal battery performance and increases EV range, while also improving battery lifespan.

ENNOVI is able to achieve this evenly distributed power spread with our precision, high-volume manufacturing methods that ensure each Cell-PLX™ metal plate has a consistent thickness, even for very large battery interconnects.

Cell-PLX™ has been designed to provide full conformance with all applicable standards that are currently used within the automotive industry and also provides the built-in flexibility for adapting to any new EV-related standards as they evolve and are adopted.

Summary

The bottom line for mitigating range anxiety and improving performance for prospective EV buyers will be continuing to enhance battery designs to boost output, while reducing the cost, size, and weight of the batteries.

Some of the key focus areas include:

- Optimizing the materials and chemistries used at the battery cell level

- Improving sourcing and supply chains for key materials such as lithium and cobalt

- Enhancing smart charging technologies to optimize charging practices

- Innovating battery design, assembly and production for high volumes and low costs

As a long-time innovator and trusted supplier to the automotive industry, ENNOVI continues to play a key role in developing underlying technologies to enable widespread adoption of EVs. Among these initiatives is our commitment to provide a full range of robust and configurable technologies for improving the cost, performance, lifecycle, and range of next generation EV batteries.