Overview

This Did You Know is part of a series that explores the Five Key Challenges to Widespread Adoption of Electric Vehicles (EVs). In this article, we drilldown to take a closer look at the issues surrounding the Resale, Recycling, and Reuse of EV Batteries.

Extended Lifecycles are Mitigating EV Resale Concerns

Although consumer worries about the potential high cost of replacing EV batteries was one of the factors that initially held back widespread EV adoption, the accumulation of ongoing empirical evidence has significantly mitigated these concerns.

According to EVbox.com, “Under current estimates, most EV batteries will last somewhere between 10-20 years before they need to be replaced.” In addition, with battery prices dropping from $1,160 per kWh in 2010 to only $128 per kWh currently, cost to replace has been significantly reduced.

The widening availability of smart charging is also helping drive longer lifecycles for EV batteries by using sophisticated software to avoid the degradation that can result from draining to zero and/or repeatedly charging to 100 percent.

In actual practice, the original batteries in new EVs rarely need to be replaced and battery lifecycles are routinely longer than the typical resale cycles for either EVs or conventional ICE automobiles. Combined with the fact that EV owners only spend about half as much on maintenance and repairs over the entire lifetime vs cost of gas-only cars, the resale market for EVs is rapidly becoming more attractive.

Taken together, these factors have not only helped boost new EV sales; they have also mitigated worries about resale values. With regard to the secondary market for reselling used EVs, according to Automotive Fleet, “the tide is beginning to turn as EVs have reached near parity with gas-powered counterparts… As new EVs improve and turn over, used EVs will depreciate less.”

Battery Reusage and Recycling

Despite the improving EV resale market and extending lifecycles, there ultimately will come a time when EV batteries will reach end-of-life, which means that proactive recycling and reuse strategies need to be in place.

It is vital that EV batteries be kept out of global waste streams to avoid negative impacts on the environment and adverse human health factors. As with other electronics systems, EV batteries contain various hazardous or toxic materials, such as the large amounts of lithium used in today’s lithium-ion batteries. Retired EV batteries can even cause destructive spontaneous fires that can spread rapidly, especially if many used batteries are stored together.

Fortunately, the potentially lucrative business opportunities in battery disposal have led to the creation of many companies around the world that provide refurbishment or recycling services

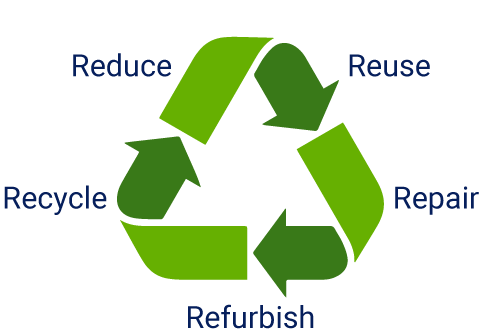

Refurbishment and Reuse

Although EV performance requirements for batteries are stringent, such as maintaining at least 80 percent of total usable capacity over the course of hundreds of partial charging cycles per year, there are other important uses for refurbished batteries. Information from McKinsey Sustainability says, “After remanufacturing, such batteries are still able to perform sufficiently to serve less-demanding applications, such as stationary energy-storage services.”

Redeploying a significant percentage of retired EV batteries within existing electrical grids has the potential to mitigate one of the biggest problems with conventional grids, which is lack of storage. Integrating storage into electrical grids will enable more effective usage of renewable energy sources and less pollution from using fossil fuel power generation to handle peak energy requirements. McKinsey estimates that reusing second-life lithium-ion EV batteries within existing power grids “could surpass 200 gigawatt-hours per year by 2030”.

Recycling

Using a process called “destructive dismantling” specialized recycling companies can properly dispose of EV batteries while recovering high-value materials such as cobalt, nickel, aluminum, and lithium. In particular, lithium is already becoming a scarce commodity as EV demand ramps up and the need for lithium is outstripping the availability from mining extraction and existing supply chains. Since most minerals needed for EVs are produced in only a handful of countries, supply chains are inherently vulnerable to price volatility and disruptions.

Recycling Li-ion batteries can be particularly challenging because the designs are often hermetically sealed and contain flammable materials. Also, lithium is difficult to recycle because it is a very light and reactive material. However, new processes such as wet-chemistry extraction vs traditional smelting are improving efficiency and, as more EVs reach end-of-life, economies of scale will help.

According to Allied Market Research, the global electric vehicle battery recycling market was valued at $138.6 million in 2017, and is projected to reach $2,2 billion by 2025, growing at a CAGR of 41.8% from 2018 to 2025. The US Department of Energy projects that “Recycled material could potentially provide one-third of United States cathode material needs for lithium-ion batteries by 2030.”

Optimizing Battery Designs for Reuse and Recycling

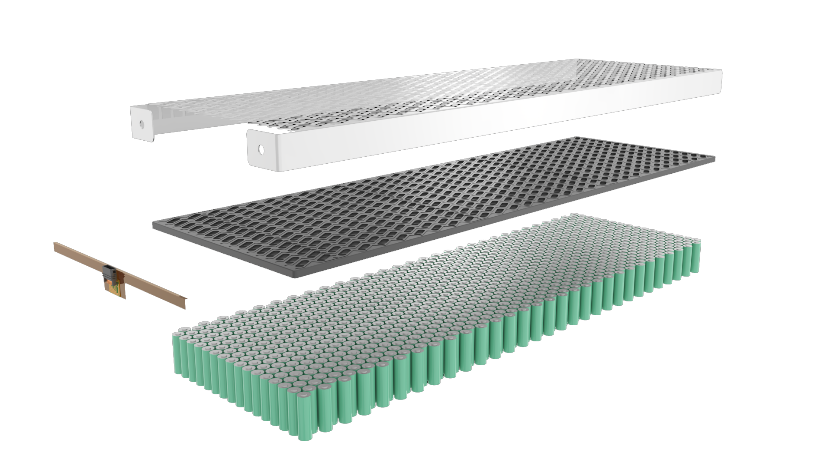

EV battery design is also a key factor that impacts the ability to refurbish and/or recycle end-of-life batteries. In particular, the way battery cells are connected together into modules and battery packs can make a significant difference not only to performance but also to reuse and recyclability.

EV batteries generally consist of a design hierarchy including the following key elements:

- Individual Cells – the smallest, packaged form of battery, which typically is a Lithium-ion unit delivering one to six volts each. Individual cells can take a range of different shapes, including cylindrical, pouch or prismatic.

- Modules – typically consisting of several cells connected together in either series or parallel.

- Battery Packs – final deployable battery systems consisting of multiple modules combined in series or parallel to provide the level of output needed for a specific application.

Battery modules typically consist of a large number of individual cells grouped together and connected to current collector plates for gathering the specified power output levels.

The Cell-PLX™ battery interconnect system from ENNOVI supports a wide range of design requirements. It addresses design complexities and space constraints with a thin and robust solution with excellent current density spread, for consistent performance and low energy loss transfer.

Looking forward, ENNOVI is also investigating the use of a removable collector plate concept that will enable Cell-PLX™ to be even more amenable to efficiently reuse and recycle. In addition, the use of removable collector plates will help lay the groundwork for future transition to solid state EV batteries, which will also provide significantly higher performance than current Li-ion batteries.

Summary

The ability to effectively reuse and recycle batteries at end-of-life will be a critical factor for meeting overall sustainability goals for the EV industry. Creating an optimal reuse and recycling capability will require

- Enhancing EV resales to reduce the number of batteries entering end-of-life

- Reworking batteries to make them suitable for use as in-grid energy storage

- Building up a robust industry for recycling batteries to reclaim scarce materials

- Enhancing battery designs and connectors to enable more efficient refurbishment or recycling

As a long-time innovator and trusted supplier to the automotive industry, ENNOVI continues to play a key role in developing underlying EV battery technologies and enhance it for reuse and recycling.