INTERCONNECT TECHNOLOGY

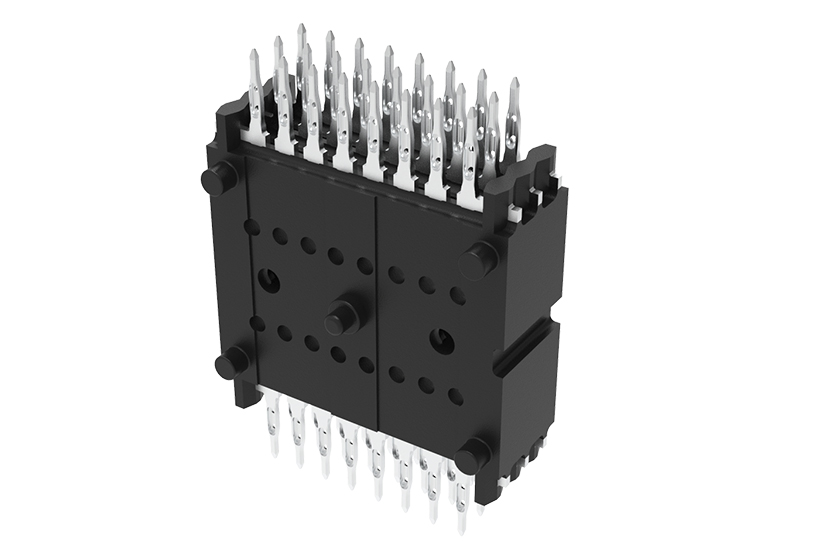

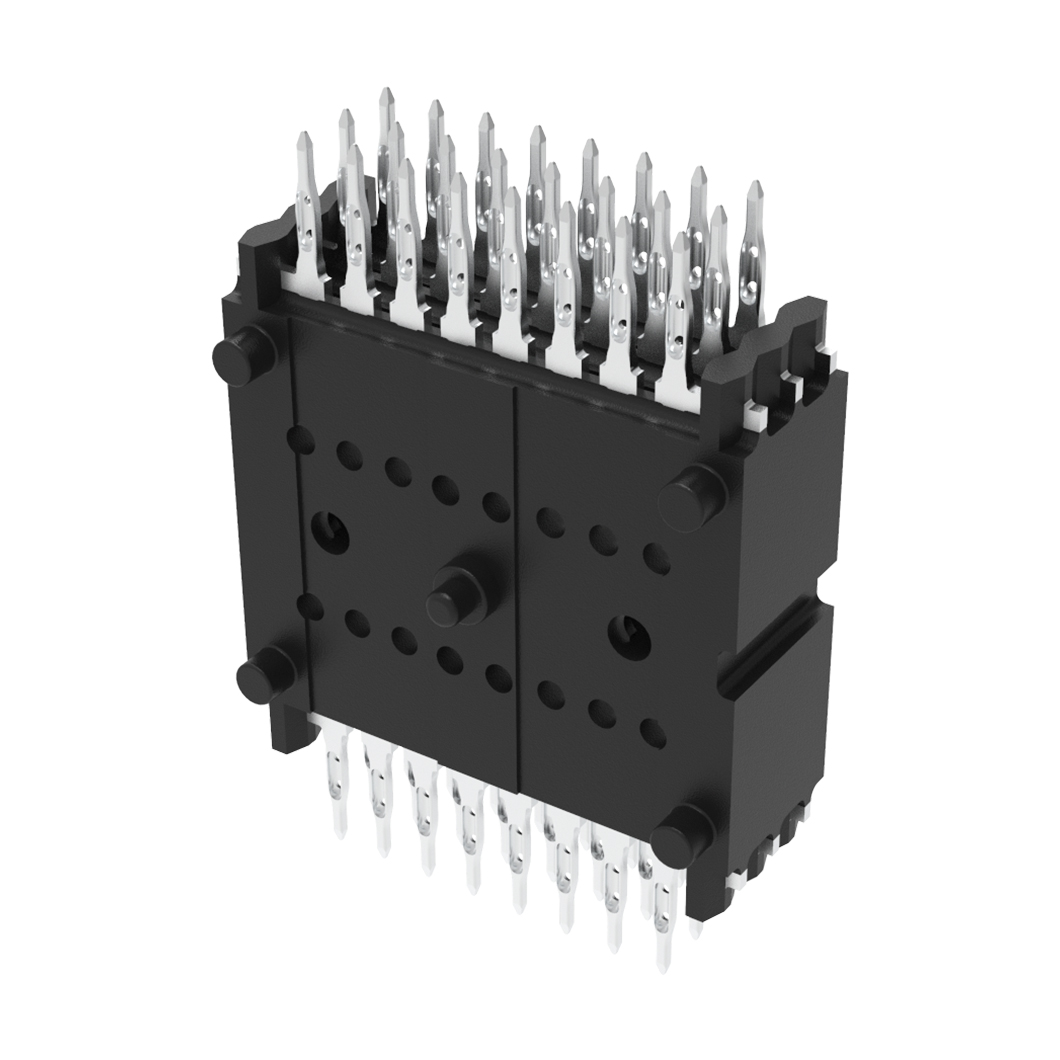

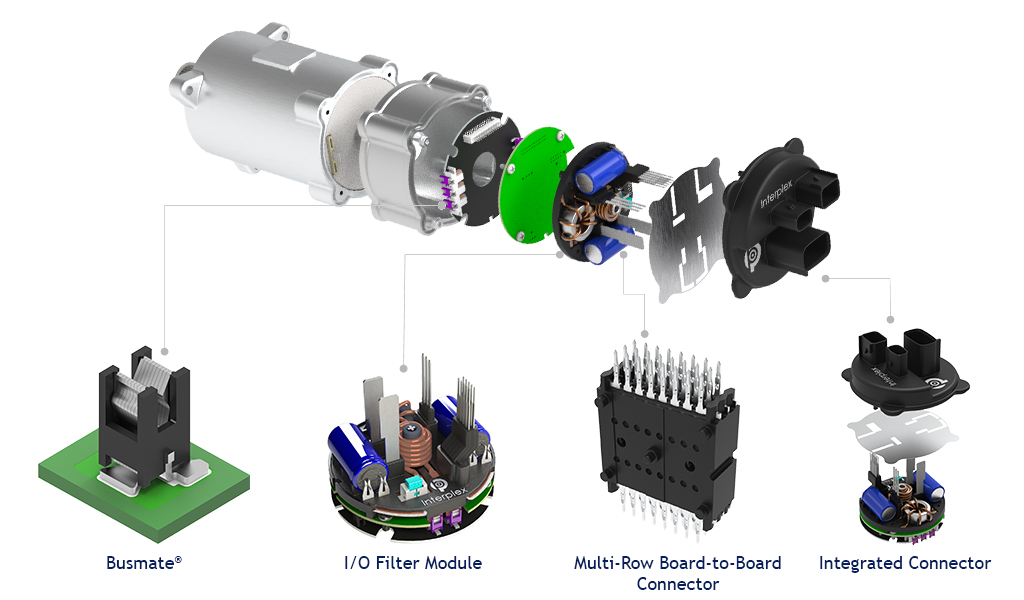

Multi-Row Board-to-Board Connectors

Interplex designs and delivers Multi-Row Board-to-Board connectors to meet the ever-changing market requirements for high performance and reliable connections for supporting customized vertical stacking of multi board assemblies with solderless connections to mitigate the costs and complexity of assembly.

Features & Benefits

Press-Fit Integration for Solderfree Assembly

By using 0.4 miniPLX™ Press-Fit with Interplex’s proprietary whisker mitigation coating, IndiCoat™, product designers can optimize PCB assembly, while creating cost-effective solderless Board-to-Board interfaces for subsequent stacking.

Highly Reliable Connection and Cost-effective Solution

Designed to meet automotive requirements for high current density, resistance to vibration, thermal shock and harsh environmental conditions, Interplex board-to-board connector solutions deliver both high reliability and cost-effective assembly.

Support for High Density Designs

Interplex multi-row connectors can accommodate a wide range of density requirements, such as using a 1.8mm x 2.0mm grid pattern with a total size up to 180 pins (in a 30 x 6 row configuration).

Applications-Specific Design Flexibility

The combination of high current carrying capacity, pin density, layout flexibility and solderless Press-Fit interfaces, make multi-row connectors an ideal solution for a wide range of applications-specific, PCB-to-PCB requirements.

Pre-Molded Headers for Custom Stacking Heights

The proprietary pre-molded biscuit design enables various stacking heights for sub-assembly stacking. Built-in interlock features help maintain tight Geometric Dimensioning and Tolerancing (GD&T) positional parameters for both connectors & PCB interfaces.

Customizable Circuit Layouts and Stacking Heights

Product designers can leverage the built-in configuration flexibility to implement a variety of circuitry layouts on the PCBs and choose pre-molded stacking heights to accommodate virtually any set of stacking specifications. Ability to easily connect the pre-molded biscuits to allow flexibility in stacking heights and the number of biscuits (or rows of circuits).

Geared for Rapid Delivery of Integrated Solutions

Our comprehensive in-house capabilities for designing, stamping, plating, molding and assembling customized connectors enable us to quickly adapt tooling and processes for specific application requirements, deliver prototypes, and ramp-up volume production with unmatched speed.

Fast Lead Times and Low Costs

By using our integrated, single-vendor solution for the entire PCB-to-PCB stacking process, product manufacturers enjoy much shorter lead times, lower costs, and avoidance of secondary operations that are inherent to multi-vendor approaches.

Global Footprint Streamlines Logistics

Interplex’s expansive global footprint and localized production facilities enable our customers to incorporate advanced interconnect technologies quickly and easily into products built anywhere in the world.

Streamlined Logistics and Support

Interplex’s distributed global organization, with design and production locations throughout the world also greatly streamline logistics and lower costs for our customers, while assuring responsive localized support and quality performance.

Highly Reliable Connection and Cost-effective Solution

Designed to meet automotive requirements for high current density, resistance to vibration, thermal shock and harsh environmental conditions, Interplex board-to-board connector solutions deliver both high reliability and cost-effective assembly.

Applications-Specific Design Flexibility

The combination of high current carrying capacity, pin density, layout flexibility and solderless Press-Fit interfaces, make multi-row connectors an ideal solution for a wide range of applications-specific, PCB-to-PCB requirements.

Customizable Circuit Layouts and Stacking Heights

Product designers can leverage the built-in configuration flexibility to implement a variety of circuitry layouts on the PCBs and choose pre-molded stacking heights to accommodate virtually any set of stacking specifications. Ability to easily connect the pre-molded biscuits to allow flexibility in stacking heights and the number of biscuits (or rows of circuits).

Fast Lead Times and Low Costs

By using our integrated, single-vendor solution for the entire PCB-to-PCB stacking process, product manufacturers enjoy much shorter lead times, lower costs, and avoidance of secondary operations that are inherent to multi-vendor approaches.

Streamlined Logistics and Support

Interplex’s distributed global organization, with design and production locations throughout the world also greatly streamline logistics and lower costs for our customers, while assuring responsive localized support and quality performance.

Types of Applications

Below are the types of applications that Multi-Row Board-to-Board Connectors are suited for:

Automotive

Steering System, Infotainment System, ECU, Sensor Module

Electrification of Vehicles

On-board chargers, Charging systems

Commercial Transportation

Steering system, Infotainment system, ECU, Sensor module

Personal Mobility

Steering system, Infotainment system, ECU, Sensor module

Industrial

Robotics, Factory automation equipment

Information & Communications Technology

Server, Storage, Routers

Medical & Life Sciences

Laboratory Device, Medical Equipment

Our Portfolio

Specifications

Material Specifications

Product Specifications

Material Specifications

| Parameter | Typical Value Range |

|---|---|

| Terminal | Copper Alloy |

| Housing | 30% GF Liquid Crystal Polymer |

| Plating | IndiCoat™ |

Product Specifications

| Parameter | Typical Value Range |

|---|---|

| Circuits | 4 up to 30 ckts per row @ 1.8mm pitch |

| Number of Rows | 1 up to 6 rows @ 2.0mm pitch |

| Board spacing | 7mm up to 30 mm |

| Current rating | max 3A/pin @ 20°C for 10mm board spacing |

| Operating Voltage | max 48V DC |

| Operating temperature | -40°C to +150°C (SAE Class II-IV) |

| Packaging | Tray |

Gallery