INTERCONNECT TECHNOLOGY

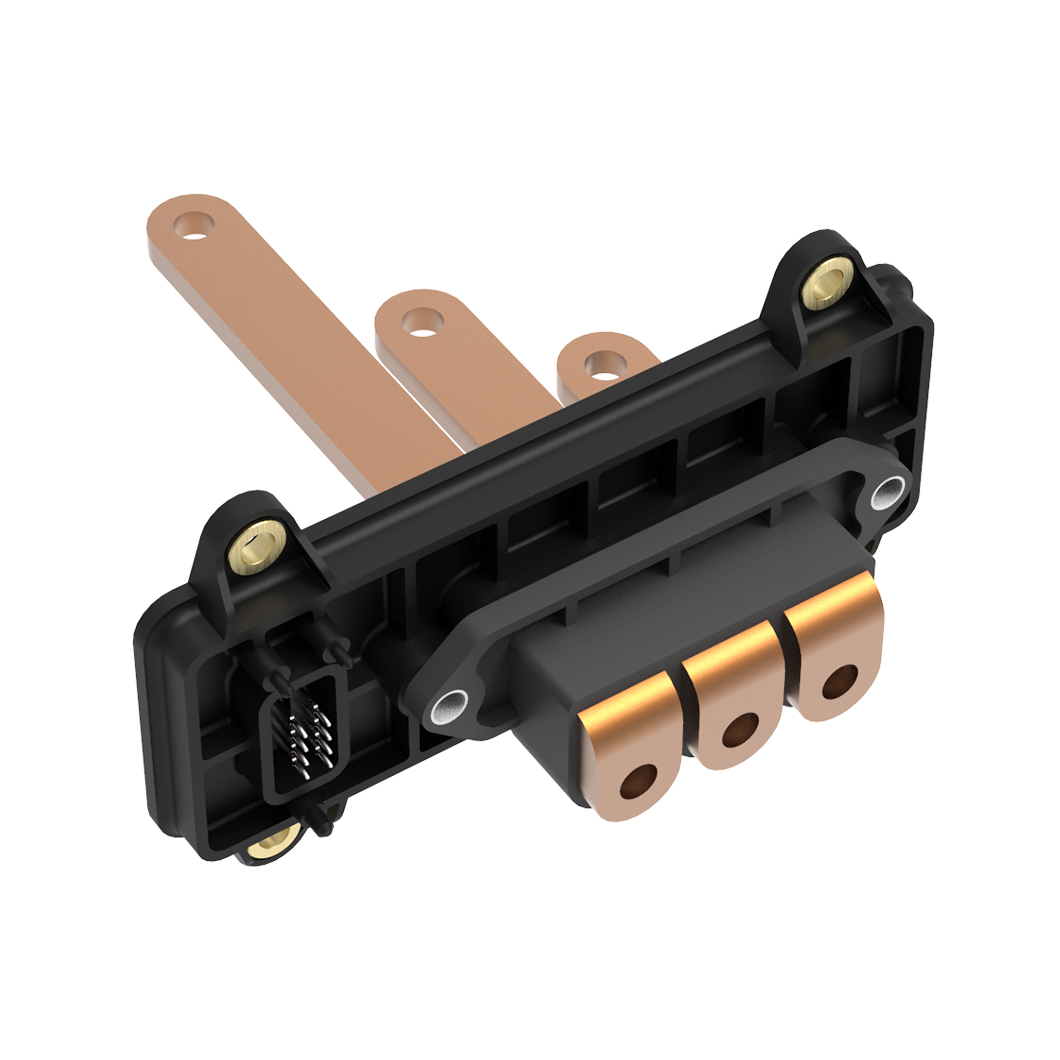

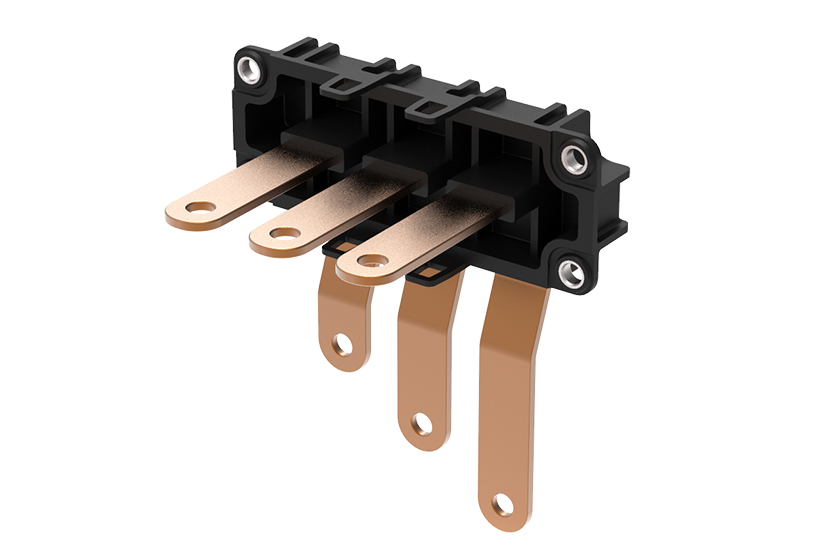

Phase Busbars

Interplex Phase Busbar Connector systems provide robust, customizable multi-phase power interfaces between AC output of inverters and input to various types of e-drive motors.

Custom options include laminate magnetic cores, current sensing, gaskets & cured sealants, high performance plastics and connections to motor stators, inverters, and drive modules.

Custom options include laminate magnetic cores, current sensing, gaskets & cured sealants, high performance plastics and connections to motor stators, inverters, and drive modules.

Features & Benefits

Wide Range of Power Applications

As power systems continue evolving in automotive and other industries, customizable busbars are increasingly important. Interplex provides a range of options to integrate multi-phase interfaces in both high and low voltage applications.

Customized To Your Requirements

Interplex busbar technologies are designed for optimal customization to meet a wide range of power applications and our multi-discipline, global logistics footprint enables rapid volume production ramp-up and delivery.

Advanced Sealing Options

Interplex’s multi-technology, application-specific approach provides options for a variety of advanced sealing options including dispense and cure, integrated gaskets, o-rings and customized sealing approaches.

Robust Performance in a Compact Size

Interplex’s holistic approach to custom, multi-phase busbars delivers unmatched performance for high power densities, while reducing size & weight and improving reliability.

Control Circuit Integration

Interplex multi-phase busbars offer customization options to integrate control circuitry directly into the busbar assemblies, thereby increasing functionality while minimizing size, weight and complexity.

Streamlined Production Processes

Customizing busbars to integrate application-specific features also can greatly streamline overall production processes by eliminating wiring errors, reducing assembly time, and simplifying supply chain logistics.

Current Sensing

By using laminated magnetic core technology, Interplex multi-phase busbars can minimize eddy currents and enable integrated current sensing capabilities.

Connection Options

Our multi-phase busbars are designed to accommodate a wide range of connection options including laser welding, brazing, bolt-on, or custom requirements.

Customized To Your Requirements

Interplex busbar technologies are designed for optimal customization to meet a wide range of power applications and our multi-discipline, global logistics footprint enables rapid volume production ramp-up and delivery.

Robust Performance in a Compact Size

Interplex’s holistic approach to custom, multi-phase busbars delivers unmatched performance for high power densities, while reducing size & weight and improving reliability.

Streamlined Production Processes

Customizing busbars to integrate application-specific features also can greatly streamline overall production processes by eliminating wiring errors, reducing assembly time, and simplifying supply chain logistics.

Types of Applications

Below are the types of applications that Phase Busbars are suited for:

Automotive

Integrated Drive Modules, Inverter AC Output, Low Voltage Servo – Steering

Electrification of Vehicles

E-Motors Systems

Commercial Transportation

Motors Systems

Personal Mobility

Integrated Drive Modules, Inverter AC Output, Motors Systems

Aerospace

Integrated Drive Modules, Inverter AC Output, Motors Systems

Industrial

Integrated Drive Modules, Inverter AC Output, Motors Systems

Options for Phase Busbars

- Sealed: Gasket and backfill design

- Flexible power busbar

- Stamped and machined contact designs

- Copper and aluminium contact

- Straight, 90 degree and custom angles

- Screwed and bolt connection options

Gallery

Phase Busbar

Phase Busbar