INCREASED LONGEVITY

Wearables Market Shifts Toward Smarter Devices

Smaller and More Complex Designs Require New Interconnect Technologies

Overview of Global Wearables Market

The worldwide shipment of wearable devices grew 1.2% during the first quarter of 2018 as total shipments reached 25.1 million units according to the International Data Corporation (IDC). While overall market growth slowed from recent quarters, the mix has shifted significantly toward more complex, smaller, and smarter devices.

Although basic wearables saw a 9.2% decline, higher priced smart wearables from the likes of Apple, Fitbit, and numerous fashion brands grew 28.4% as consumer preferences continued to shift towards smarter devices. In addition to watches and wrist bands, which accounted for 95% of the shipments during the quarter, sensor-laden clothing grew 58.6% year over year. The majority of these were stepcounting shoes, followed by items such as shirts, shorts, and other clothing with fitness tracking functionality.

Although basic wearables saw a 9.2% decline, higher priced smart wearables from the likes of Apple, Fitbit, and numerous fashion brands grew 28.4% as consumer preferences continued to shift towards smarter devices. In addition to watches and wrist bands, which accounted for 95% of the shipments during the quarter, sensor-laden clothing grew 58.6% year over year. The majority of these were stepcounting shoes, followed by items such as shirts, shorts, and other clothing with fitness tracking functionality.

Figure 1-Smart Wearable Devices Are Growing in Popularity

“With the move towards smarter devices, we're also starting to see hints of where the wearables market is headed. Additional sensors, years of underlying data, and improved algorithms are allowing pillars of the industry like Fitbit and Apple to help identify diseases and other health irregularities. Meanwhile, roughly one third of all wearables included cellular connectivity this quarter, which has allowed new use cases to emerge"

“With the move towards smarter devices, we're also starting to see hints of where the wearables market is headed. Additional sensors, years of underlying data, and improved algorithms are allowing pillars of the industry like Fitbit and Apple to help identify diseases and other health irregularities. Meanwhile, roughly one third of all wearables included cellular connectivity this quarter, which has allowed new use cases to emerge"

– Jitesh Ubrani, senior research analyst for IDC Mobile Device Trackers

IDC predicts that the overall wearables market will grow 13.4% (CAGR) over the next five years, with 219.4 million units shipping in 2022. While the smartwatch market share is expected to increase in the next few years from 32.8% in 2018 to 38.3% in 2022, fitness band market share is expected to shrink during the same period from 35.9% to 22%.

Advanced Interconnects Are Key to Increasing Functionality in Smaller Devices

With new generation wearable devices packing higher functionality into smaller compact form factors, product designers are constantly seeking advanced interconnect solutions to support higher circuit densities, smaller form factors and cost-effective high-volume production requirements.

One of the key enabling technology arenas that supports this trend is the evolution of new interconnect technologies that are both smaller and more configurable. It has become impractical to design next generation compact wearables using conventional standard off-the-shelf interconnects, because their lack of flexibility generally takes up too much space for connecting miniaturized sub-assemblies.

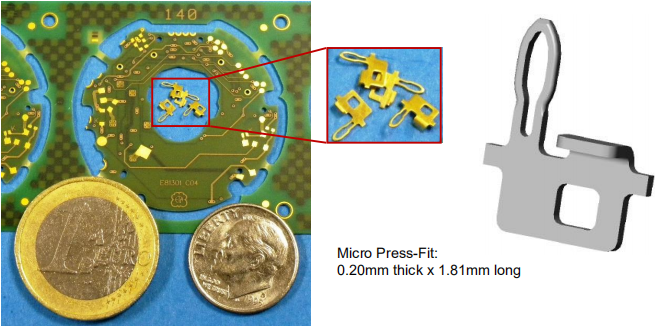

Tightly integrating solderless Press-Fit interconnect designs directly into wearables subassemblies has become an important technique that enables smaller footprints and reduces wasted space, while also streamlining production for higher volumes.

For example, as shown below, new micro Press-Fit interconnects can provide completely solderfree connections between smartwatch PCBs, motor coils and sub-assemblies.

One of the key enabling technology arenas that supports this trend is the evolution of new interconnect technologies that are both smaller and more configurable. It has become impractical to design next generation compact wearables using conventional standard off-the-shelf interconnects, because their lack of flexibility generally takes up too much space for connecting miniaturized sub-assemblies.

Tightly integrating solderless Press-Fit interconnect designs directly into wearables subassemblies has become an important technique that enables smaller footprints and reduces wasted space, while also streamlining production for higher volumes.

For example, as shown below, new micro Press-Fit interconnects can provide completely solderfree connections between smartwatch PCBs, motor coils and sub-assemblies.

Figure 2-Micro Press-Fit Integrates Miniature Assembliesfor Smartwatches

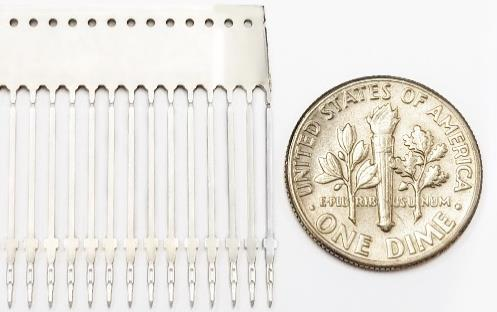

In other situations, continuous stampings of miniaturized PressFit interconnects, such as the 0.4mm MiniPLX, can provide small, automation-friendly interconnects that reduce the pitch between interconnects and enhance efficient integration of solderless assembly processes for smart wearables.

This enables product designers to fit more functionality into smaller products with finer pitch spacing and a better use of PCB real estate, while simultaneously increasing production efficiency.

This enables product designers to fit more functionality into smaller products with finer pitch spacing and a better use of PCB real estate, while simultaneously increasing production efficiency.

Figure 3-Continuous Stamped 0.4mm MiniPLX Press-Fit

Summary

The wearables industry is reaching a key inflection point in which consumers are gravitating toward higher functionality in smaller form factors. This requires designers and manufacturers of new wearable devices to not only pack more capabilities into the chips, PCBs and subassemblies, but to also minimize the space required to connect all these pieces together.

Instead of being forced to use relatively large individual pins and solder-based interconnect methods, the newest generations of miniaturized Press-Fit interconnects give product designers flexible alternatives that can reduce the pitch between pins, optimize PCB real estate, enable more efficient spacing between sub-assemblies and reduce overall costs while increasing production volumes.

Instead of being forced to use relatively large individual pins and solder-based interconnect methods, the newest generations of miniaturized Press-Fit interconnects give product designers flexible alternatives that can reduce the pitch between pins, optimize PCB real estate, enable more efficient spacing between sub-assemblies and reduce overall costs while increasing production volumes.

For more information

For more information about our Press-Fit interconnect technologies, visit our website at https://interplex.com/press-fit or drop us an email at communications@interplex.com.